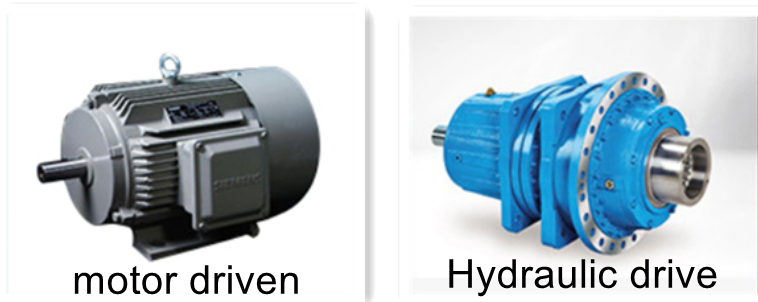

In the bulky waste crushing and processing system, there are two commonly used driving methods for the crusher.

Many customers do not know which of these two driving methods should be selected. Today we will introduce the hydraulically driven large waste crushing in detail.

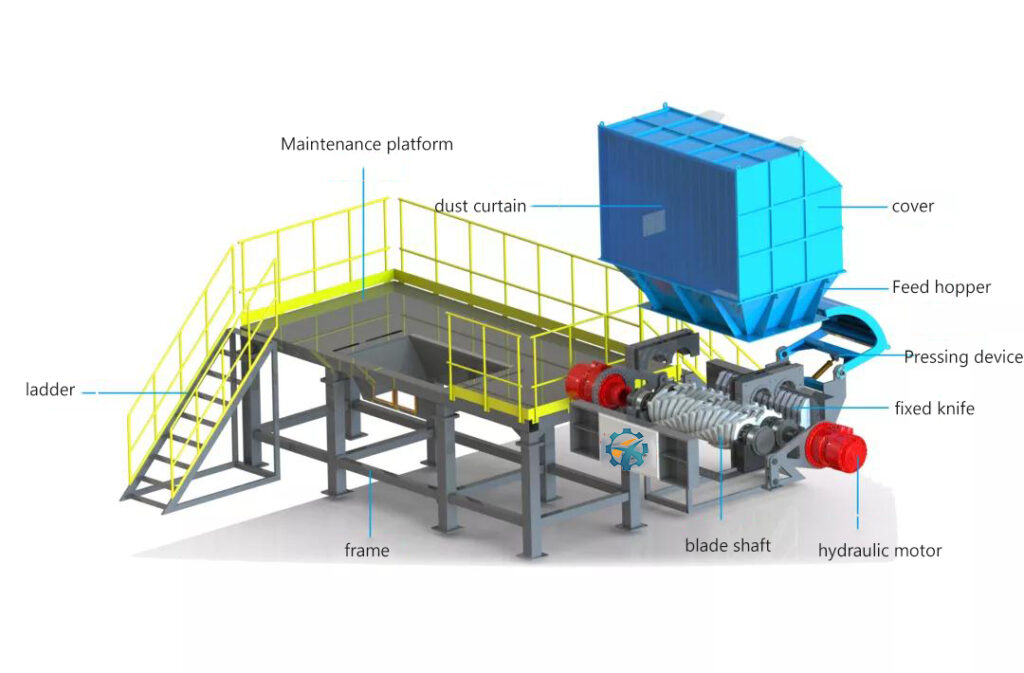

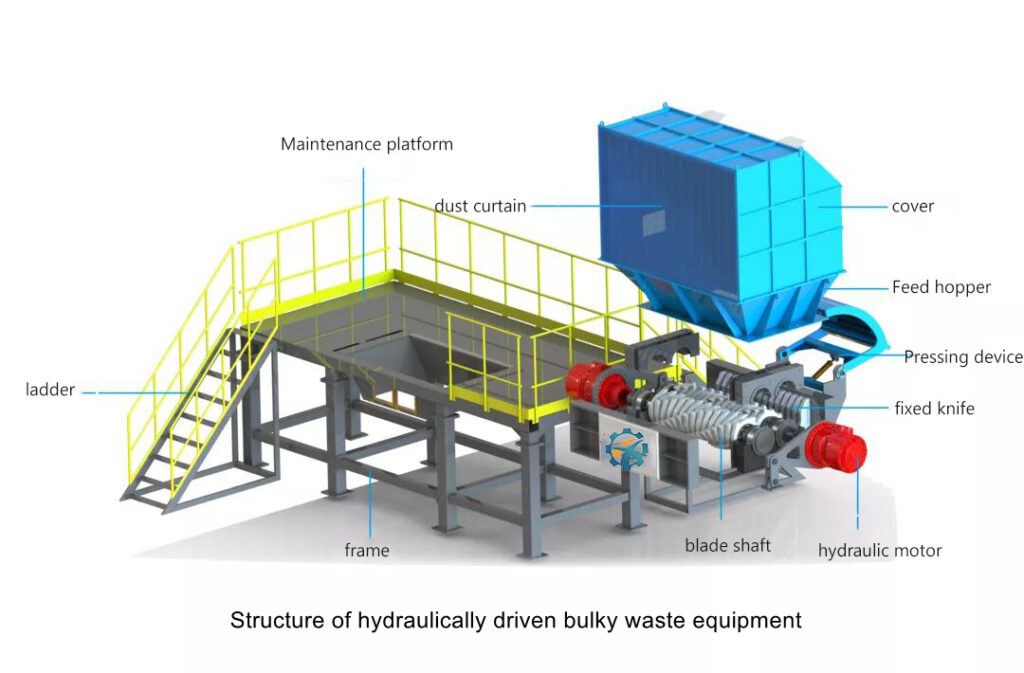

1.Schematic diagram of hydraulic motor operation

2.Hydraulic motor main performance characteristics

- Strong impact resistance and good stability

- Can realize safe and stable variable and parking braking

- It can realize free wheel working condition

- Various installation methods and hollow shaft design

- It has good stability at low speed and can run smoothly at very low speed

- It has high mechanical efficiency and volume efficiency

- Large output torque, wide speed range, can directly replace high speed motor reducer device

- Reversible direction of rotation

- High power to mass ratio

- Good reliability, easy maintenance

3.Hydraulic motor drive system

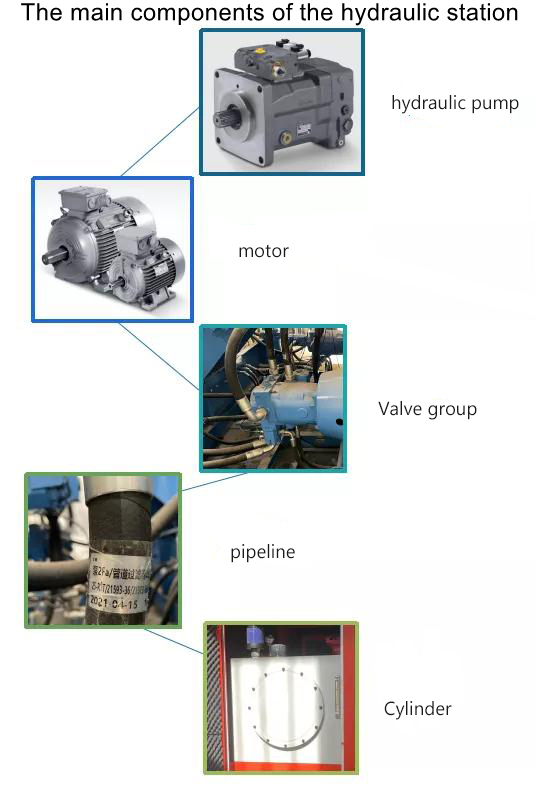

4.The main parameters and functions of the hydraulic system are as follows:

- Crusher drive mode: hydraulic motor drive (not through reducer)

- Hydraulic pump drive mode: three-phase asynchronous motor

- Normal working pressure of hydraulic system: 260-350Bar, rated torque 100000m

- The main components of the hydraulic system are provided with a detailed selection calculation book and the original factory sample parameters to support

- The connecting parts of the hydraulic system, such as oil pipes, joints, sealing rings, etc., are all made of high-quality products to ensure the sealing of the hydraulic oil circuit and the stable operation of the equipment

- The hydraulic system is equipped with a hydraulic limit sensing device. Once oil leakage occurs, it will automatically stop and display the cause of the failure on the LCD screen

- Our company promises to provide free installation and debugging hydraulic oil (Great Wall brand 46# anti-wear hydraulic oil), lubricating oil and hydraulic oil and lubricating oil required within the first year of the warranty period, and the hydraulic oil shall be replaced at least twice